Cosmetic Container Inspection

Surface Inspection, Positioning Errors and OCR

Customer Request

Our customer produces up to 8,000 cosmetics containers per hour. Initially, the containers were randomly inspected manually by the quality department every one to two hours. In addition, gross defects were already detected by a classic inspection system.

Maddox AI has integrated three individual camera systems on the existing production line so that the front, back and bottom of the containers can be inspected. In addition to classic damages, the label as well as other imprints such as batch stamps are inspected.

Random manual inspections were carried out in three shifts by one employee. The detection accuracy varied depending on the inspector.

All products are 100% automatically inspected according to a precise defect book definition.

The plant received several customer complaints per year, which had to be manually rechecked.

No further customer complaints have been received since the installation of Maddox AI.

Since the inspection results were not digitized, no regular structured root cause analysis was performed.

Thanks to the digitized inspection process, the production scrap rate has been reduced by 20 %.

Sounds like what you need?

Do you have questions about this solution or your very specific application?

Our experts will be happy to advise you!

More Case Studies

Browse through some of our selected case studies. If you have any questions about individual examples or your specific use case, please feel free to contact us at any time!

Pharmaceutical and Medical

- All

- Automotive

- Consumer Goods

- Electronical

- Energy Technology

- Food and Beverages

- Logistics

- Metal

- Pharmaceutical and Medical

- Plastic

Component Detection

- All

- Code Recognition

- Component Detection

- Positioning Errors

- Surface Inspection

Cardboard

- All

- Cardboard

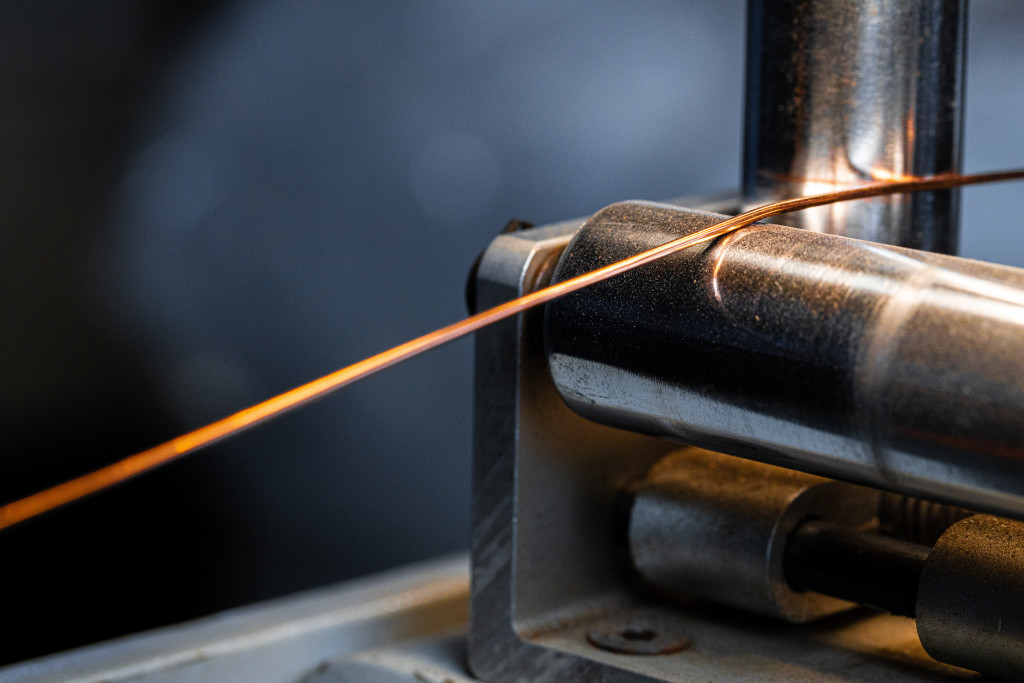

- Copper

- Dough

- Metal

- Paper

- Plastic

- Rubber

- Steel