Our Case Studies

From Theory to Practice

Maddox AI has already automated numerous quality inspections in various industries and with different challenges. Read our case studies to learn more about inspection cases that have already been solved, what problems our customers had to deal with before implementing Maddox AI and to what extent they benefit from our individual solution.

Case Studies

Overview of Our Case Studies

Here you will find an overview of selected case studies. If you have any questions about individual examples or your specific use case, please feel free to contact us at any time!

Industry

Pharmaceutical and Medical

Pharmaceutical and Medical

- All

- Automotive

- Consumer Goods

- Electronical

- Energy Technology

- Food and Beverages

- Logistics

- Metal

- Pharmaceutical and Medical

- Plastic

Application

Component Detection

Component Detection

- All

- Code Recognition

- Component Detection

- Positioning Errors

- Surface Inspection

Material texture

Cardboard

Cardboard

- All

- Cardboard

- Copper

- Dough

- Metal

- Paper

- Plastic

- Rubber

- Steel

Cosmetic Container Inspection

Maddox AI's software, as well as the implementation of three individual camera systems, can reliably inspect surfaces, labels and imprints.

Consumer Goods

Positioning Errors

Surface Inspection

Plastic

Full Case Study

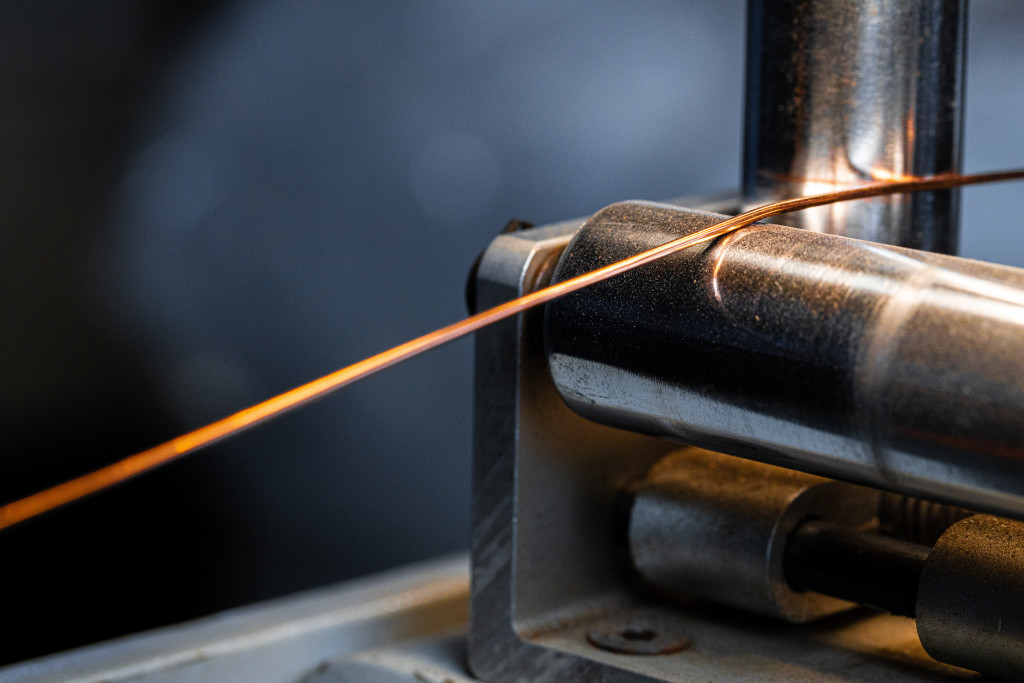

Fully Automated Wire Inspection

Surface defects such as dents, burnt areas or insulation defects can be reliably checked automatically with the help of Maddox AI.

Energy Technology

Surface Inspection

Copper

Full Case Study

Inspection Cell for Plastic Seals

By integrating a rotating inspection cell with three cameras in combination with Maddox AI's software, the plastic seals are reliably inspected 100% of the time.

Plastic

Surface Inspection

Plastic

Full Case Study

Inspection of Ball Bearings

Maddox AI successfully automates the inspection of impact points, incorrectly mounted components and scratches on ball bearings.

Automotive

Metal

Component Detection

Surface Inspection

Steel

Full Case Study

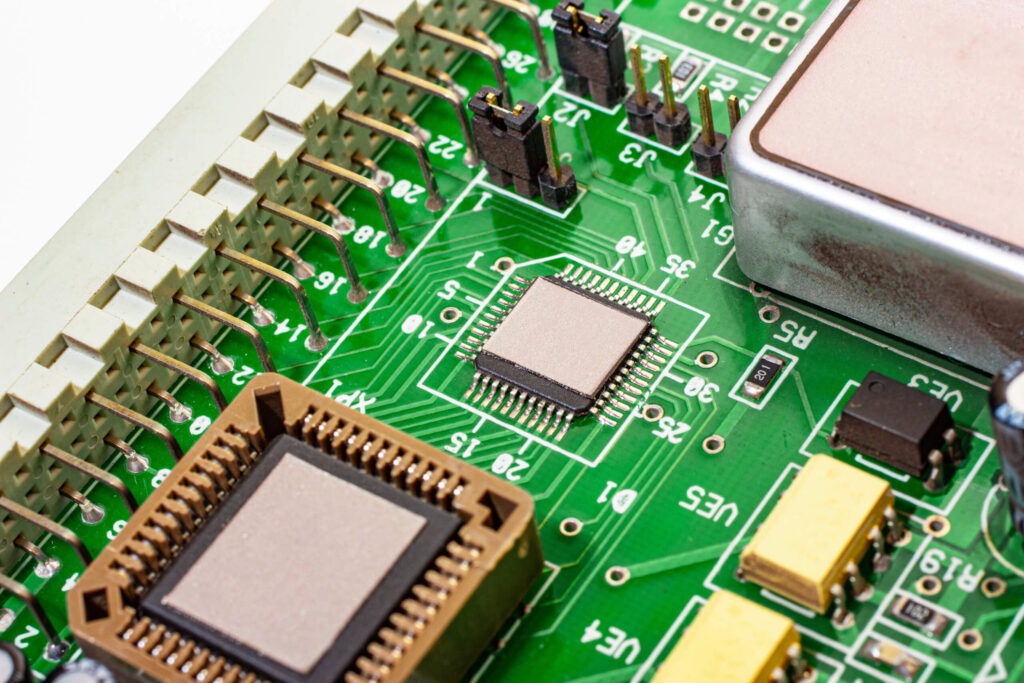

Inspection of Printed Circuit Boards

Thanks to Maddox AI's device and software, incorrectly assembled components and other damages can be detected and tracked to a specific PCB.

Electronical

Code Recognition

Component Detection

Surface Inspection

Copper

Plastic

Full Case Study

Label Recognition on Cardboard Boxes

Thanks to Maddox AI, the codes and labels on different cartons are reliably recognized, read, matched as well as rejected and re-evaluated in case of discrepancy.

Logistics

Code Recognition

Cardboard

Full Case Study

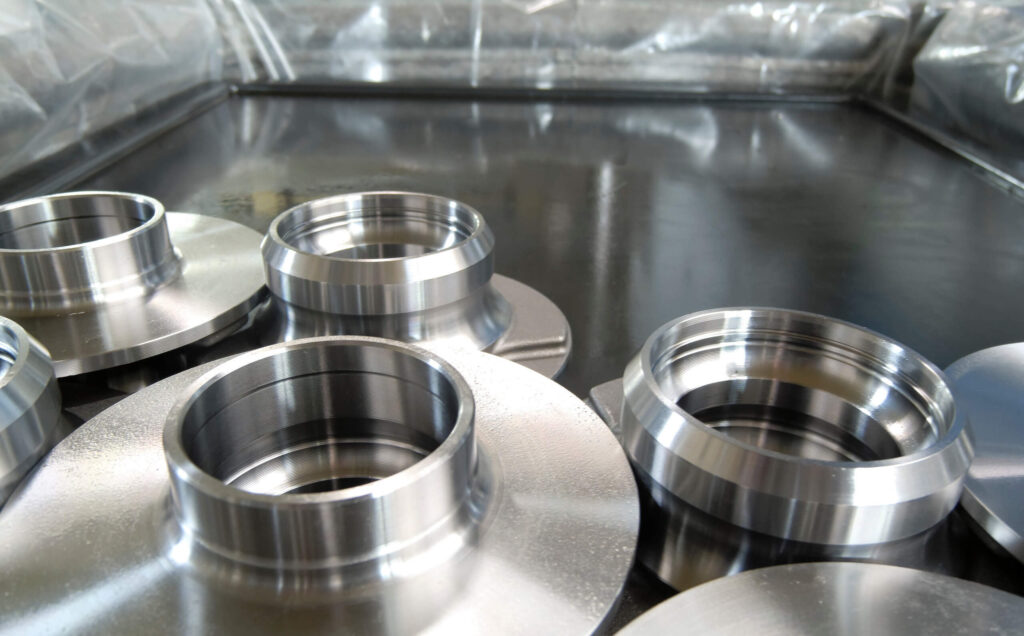

Optimization of Turned Parts Inspection

Thanks to Maddox AI, the turned parts can be inspected 100% from all sides and thus are reliably checked for craters, impact points and grooves.

Automotive

Metal

Surface Inspection

Metal

Full Case Study

Tractor Inspection

Maddox AI ensures that all relevant parts of a customer-specific order have been correctly mounted on a the customer's tractor.

Automotive

Component Detection

Rubber

Steel

Full Case Study