Quality Control With Maddox AI: Your Benefits

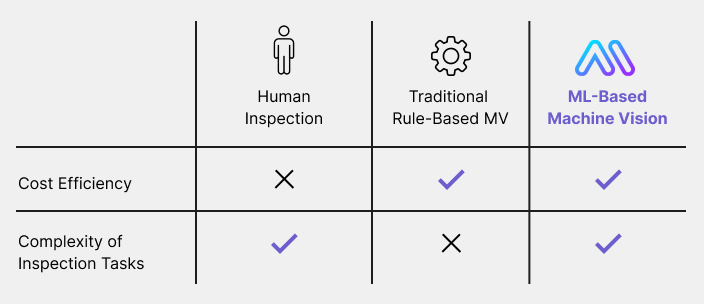

As an AI-based solution, Maddox AI clearly stands out from conventional quality control systems and offers you numerous benefits over classic inspection systems.

Cost-Efficient Quality Control for Complex Components and Surfaces

Maddox AI combines the reliability of classic vision systems with the ability to accurately inspect complex components and surfaces.

This means that even components that are sometimes lighter or darker, glossier or duller, depending on the production batch, can be reliably inspected automatically.

Reduced Pseudo Scrap and Minimised Calibration Effort

Unlike conventional, rule-based quality control systems, Maddox AI recognises that OK components may look different due to production variability, such as differences in brightness, darkness or matte surfaces, without necessarily being classified as a relevant defect criterion. Thanks to this adaptive capability, Maddox AI can drastically reduce pseudo scrap without the need for time-consuming manual recalibration of the model.

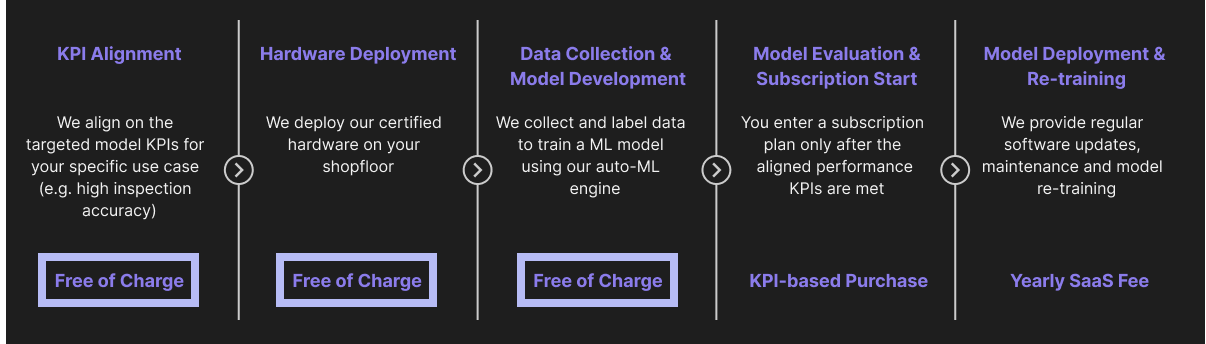

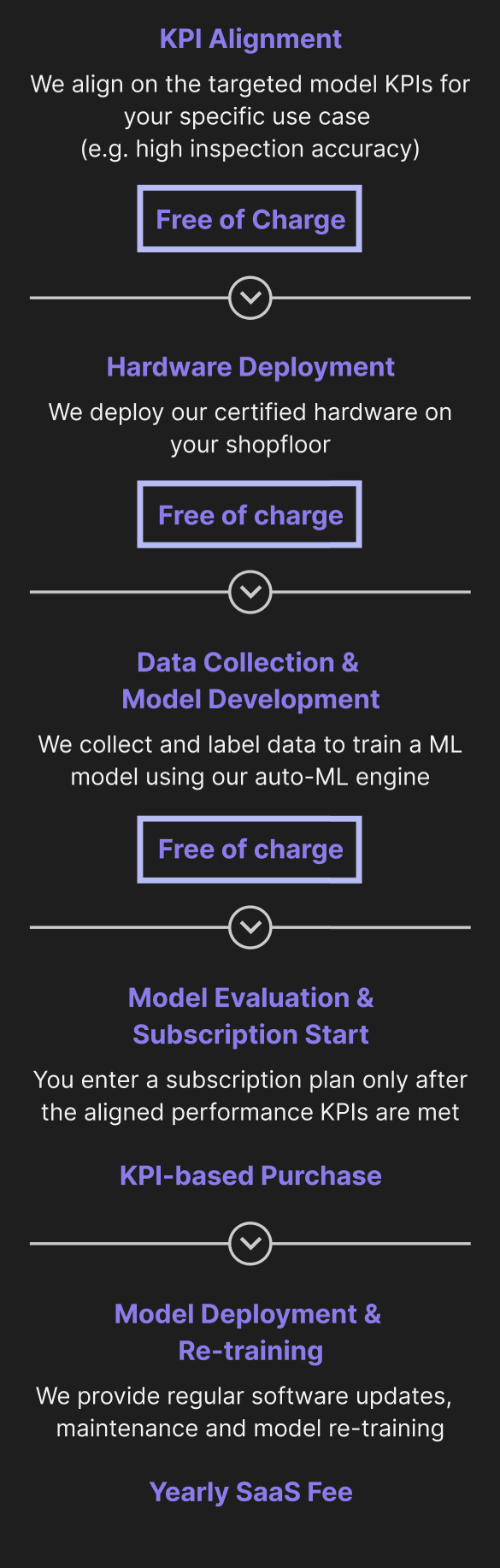

No Investment Risk:

Payment Only After Successful Model Approval

Free White Paper: Why Aren't More Companies Using AI-Based Visual Inspection Systems?

Train AI Models With a Few Clicks

Gain Powerful Production Insights Through

Our Cloud Software

- Our cloud software gives you valuable insights into your production. Our platform provides access to all relevant production KPIs such as Pareto analysis and defect concentration diagrams. This allows you to easily identify optimisation potential, such as structural defects, in your production process and drive their implementation.

- Maddox AI informs you proactively and in real time when error limits are exceeded. This is done via various communication channels such as email or SMS. This allows you to intervene in time and prevent the production of scrap over a longer period of time.