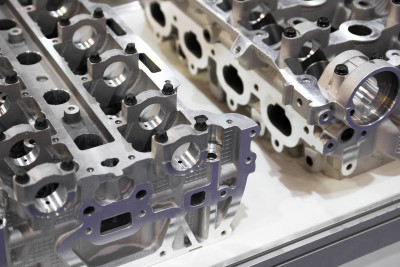

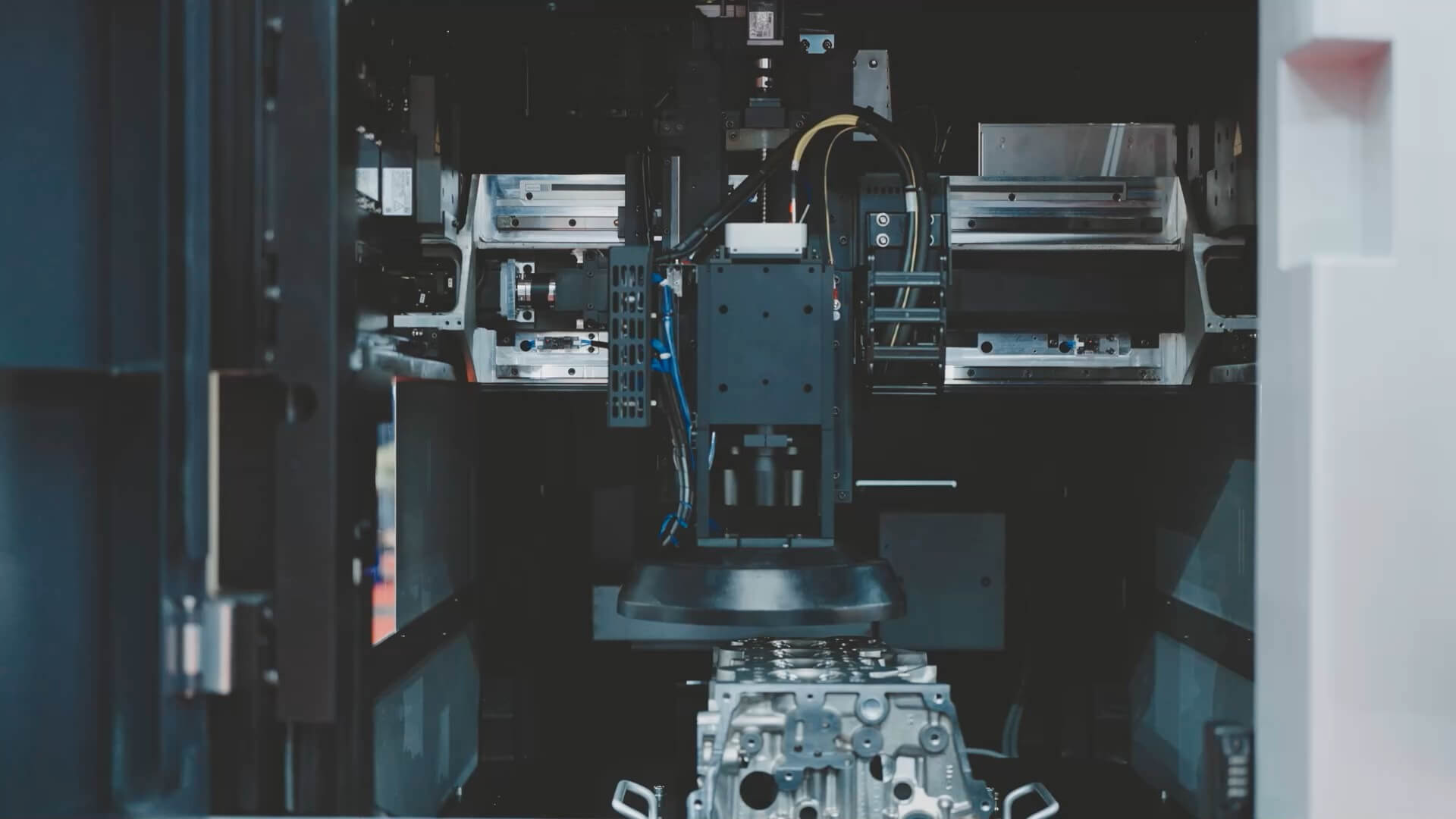

AI-Based Visual

Quality Control

With Maddox AI, you can reliably automate and digitise your quality control by simply annotating a few defect images - without any investment risk!

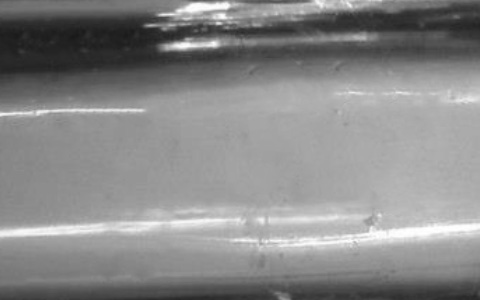

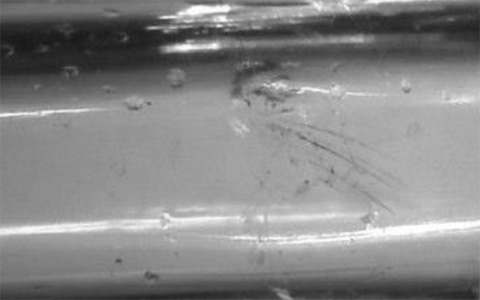

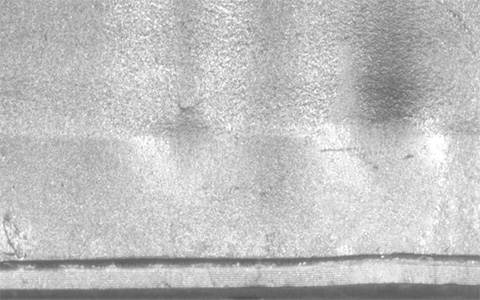

About our solutionOK  |

Scratch  |

Quality Control

With Maddox AI, you can reliably automate and digitise your quality control by simply annotating a few defect images - without any investment risk!

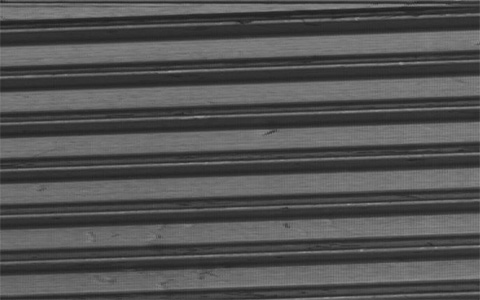

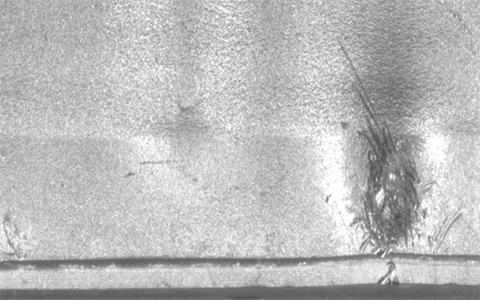

About our solutionOK  |

Burr  |

Quality Control

With Maddox AI, you can reliably automate and digitise your quality control by simply annotating a few defect images - without any investment risk!

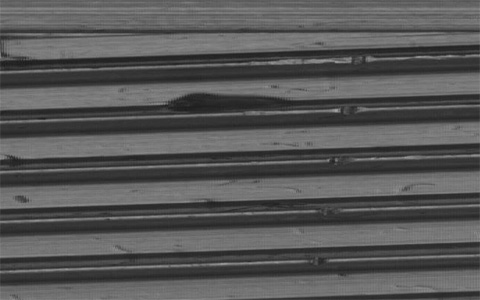

About our solutionOK  |

Impact Point  |

Maddox AI: Your Benefits at a Glance

Free White Paper: Why Aren't More Companies Using AI-Based Visual Inspection Systems?

Our Cloud Software at a Glance

Easy creation and maintenance of digital fault catalogues

Intuitive annotation of errors to be detected automatically

Transparent feedback on whether data quality is sufficient to train AI models

Train AI models with a few clicks

Reliable updating of models in your production lines

Easy creation and maintenance of digital fault catalogues

Intuitive annotation of errors to be detected automatically

Transparent feedback on whether data quality is sufficient to train AI models

Train AI models with a few clicks

Reliable updating of models in your production lines

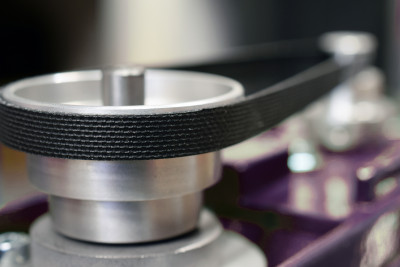

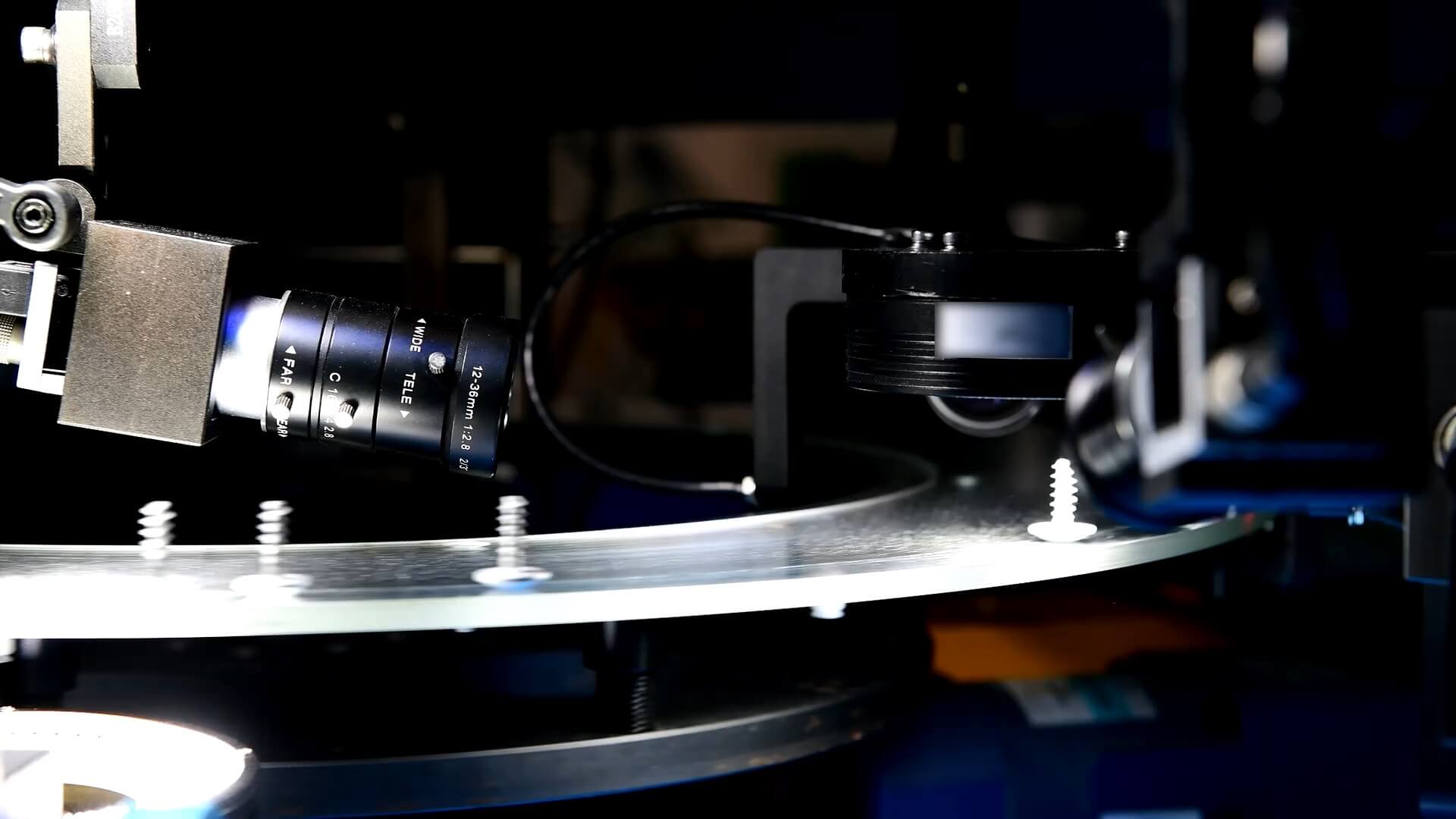

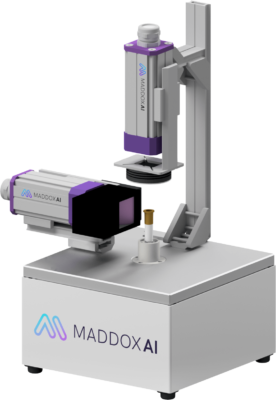

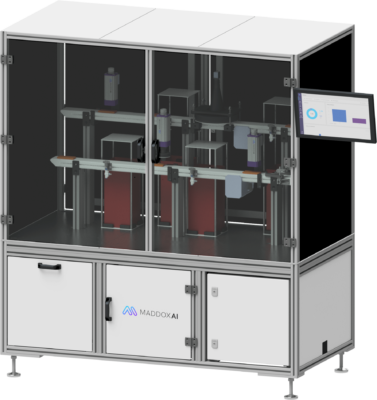

Powerful Hardware Solutions for Individual Inspection Tasks

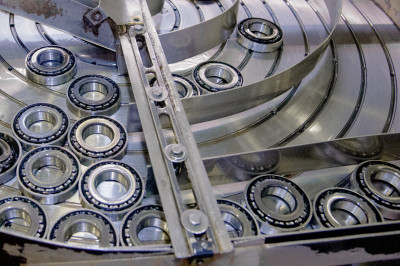

Many Inspection Tasks Can Be Automated With Maddox AI

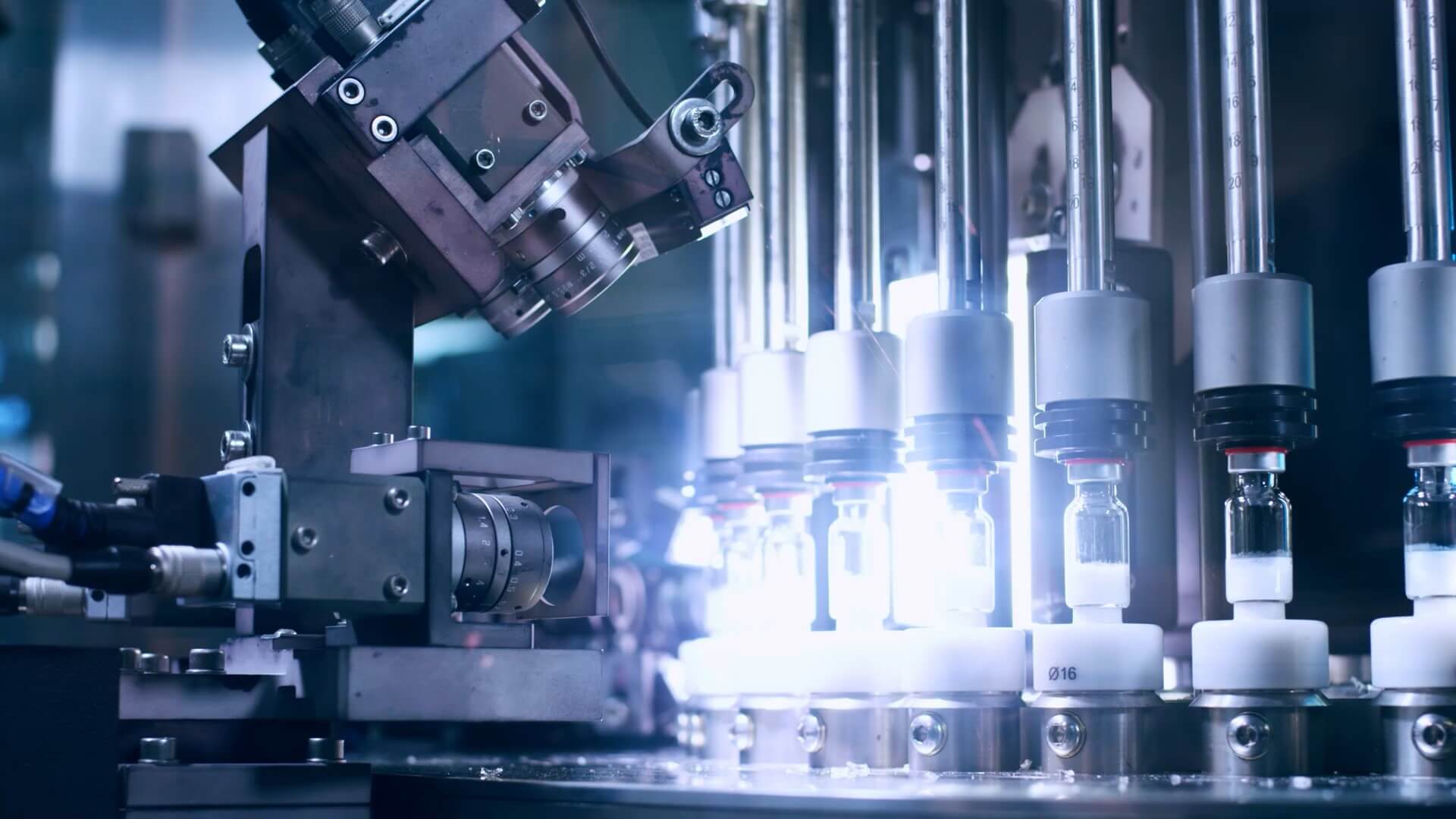

Pharmaceutical and Medical

- All

- Automotive

- Consumer Goods

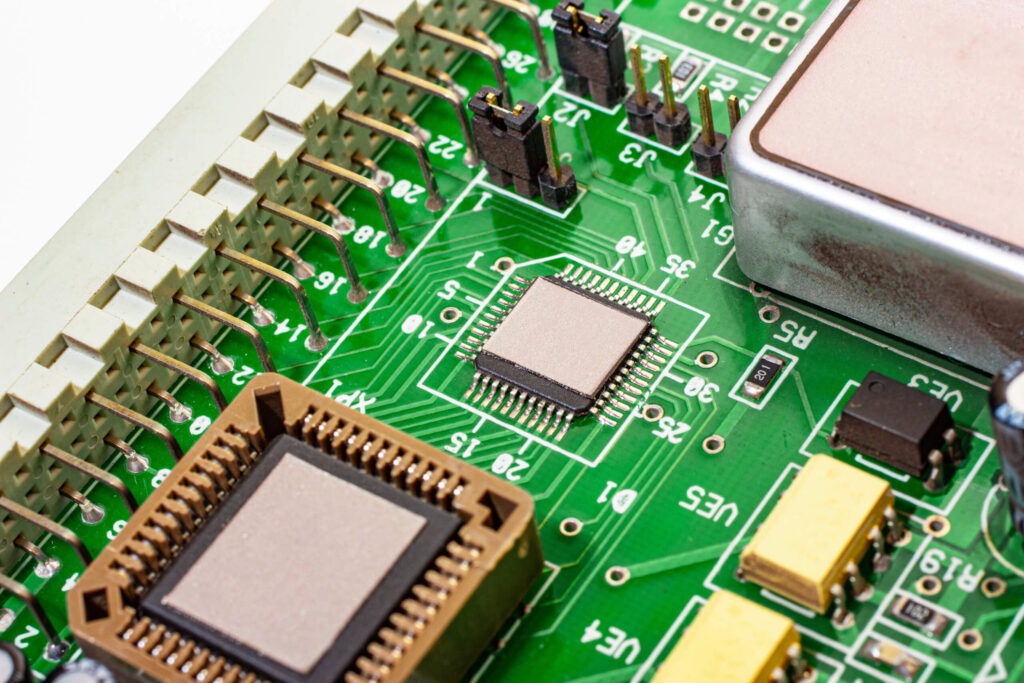

- Electronical

- Energy Technology

- Food and Beverages

- Logistics

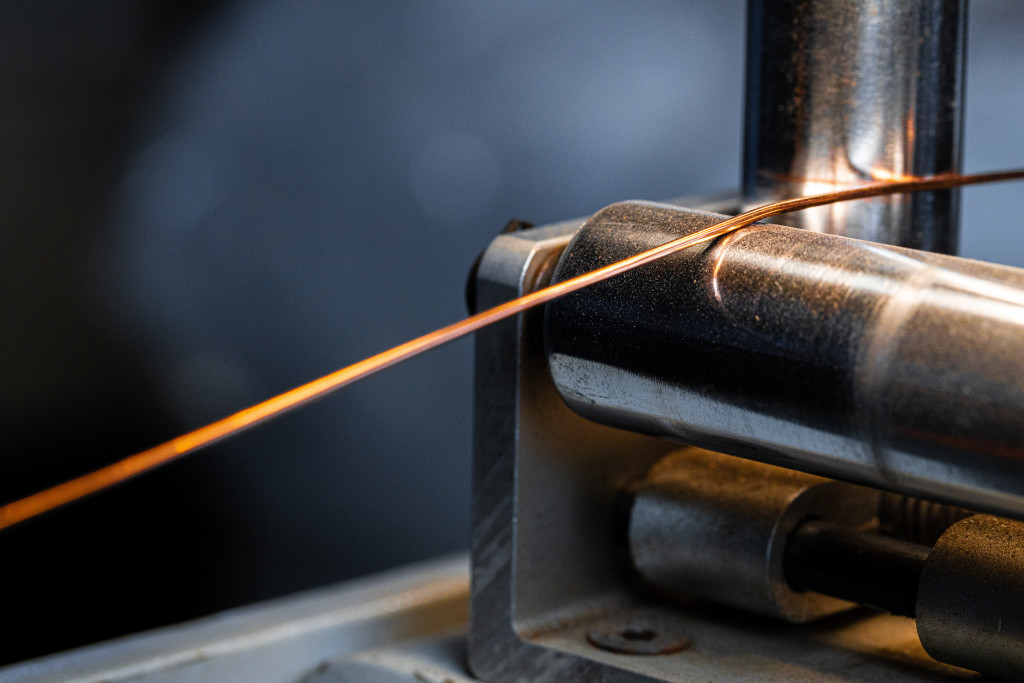

- Metal

- Pharmaceutical and Medical

- Plastic

Component Detection

- All

- Code Recognition

- Component Detection

- Positioning Errors

- Surface Inspection

Cardboard

- All

- Cardboard

- Copper

- Dough

- Metal

- Paper

- Plastic

- Rubber

- Steel

Industry Overview: Diverse Applications in Quality Control

Your data is safe with us!

Our information management system is certified to meet the latest ISO 27001:2022 standards, ensuring the highest level of data security. Rest assured that your valuable data is well protected in our care. With continuous monitoring and improvement, we prioritize your information security at every step. Additionally, all data is processed and hosted exclusively in Germany.