AI-Based Quality Inspection in the Plastics Industry

Maddox AI offers customised solutions for optimising quality inspections in the plastics industry.

Plastics are a modern and demanding raw material that brings with it special inspection requirements. Maddox AI is used in particular for quality inspections where conventional, rule-based inspection systems reach their limits or struggle with problems related to pseudo-rejects. This occurs, for example, with components that have slightly different degrees of brightness or gloss due to production batches.

Applications of Maddox AI in the Plastics Industry

Maddox AI offers customised solutions for the plastics industry to increase quality and efficiency in production. Our AI-powered technology enables the detection of irregularities and defects in plastic parts, which increases overall production quality and minimises waste. In addition, Maddox AI automates the monitoring of production batches to ensure consistent results and reduce production costs.

With Maddox AI, every automation project is also always a digitisation project. Maddox AI processes the data captured during automated visual inspection, including images and metadata, in the cloud software to enable detailed analytics such as defect Pareto analyses, defect heatmaps and dashboards. You are actively notified by Maddox AI (e.g. via email or SMS) when too much scrap is produced. In this way, you can ensure that excessive scrap does not occur over a longer period of time.

The quick identification of defects and deviations increases the efficiency of production processes and ensures competitiveness in the plastics industry.

The Following Use Cases, for Example, Can Be Inspected Through Maddox AI:

Detection of irregularities and defects: To increase the overall quality of plastic parts and minimise scrap, even if production batches have slightly different visual characteristics.

Automated monitoring of production batches: To ensure that consistent results are achieved in production, even if differences in brightness or gloss occur.

Surface smoothness: To identify surface irregularities, scratches or dents to ensure smooth texture and a high quality finish.

Detection of inclusions and foreign objects: Identification of inclusions, foreign bodies or irregularities that could affect the appearance or texture of plastic products.

Detection of deformations: Identification of deformations or distortions that may occur during the manufacturing process.

Precise component verification: Checking individual components for their exact specifications and ensuring error-free assembly.

Sharp edges and precision moulds: Inspection of sharp edges and precision moulds to ensure that plastic parts are manufactured without burrs or unclean edges.

Identification of surface marks: Detection of unwanted marks, imprints or dirt on the surface to maintain aesthetic quality.

Checking engravings and embossings: Checking engravings or embossing on plastic surfaces using OCR.

Identification of part numbers: Precise recording of part numbers on components using OCR to enable accurate allocation and prevent incorrect orders.

Reading of bar and QR codes: Recognition of codes for accurate identification and verification of components and products.

Traceability of products: Complete traceability of products from manufacturing to the end user to ensure safety and quality throughout the supply chain.

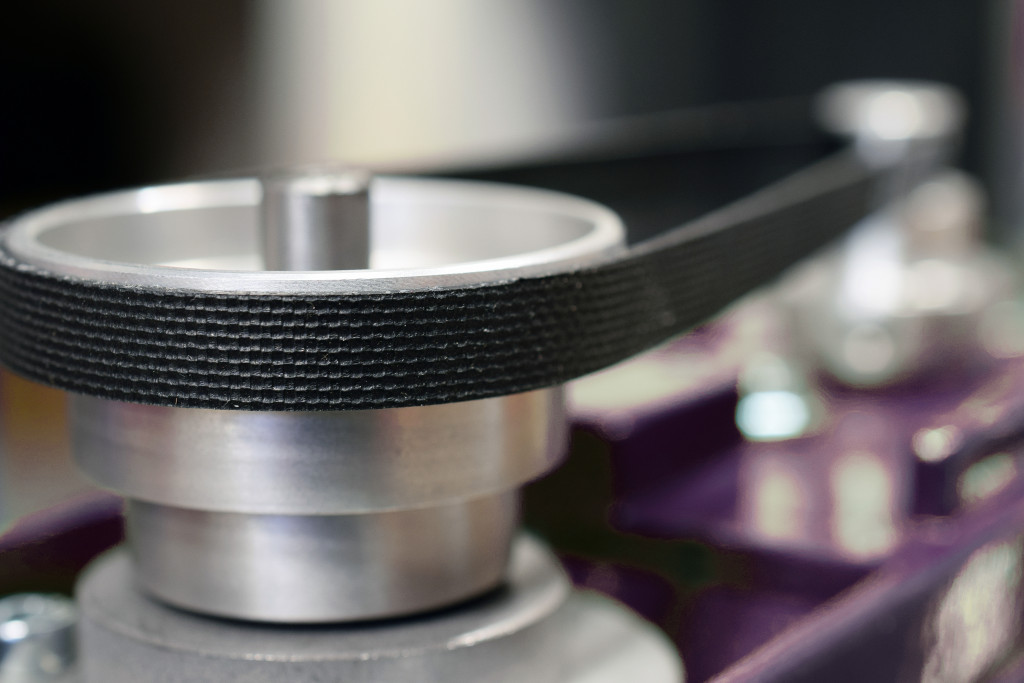

Example: Inspection Cell for Plastic Seals

Do you have questions about specific possible applications of Maddox AI?

Our experts will be happy to advise you!