AI-Based Inspection in the Electrical Industry

Maddox AI can be used to optimise and automate a wide range of visual inspections in the electrical industry.

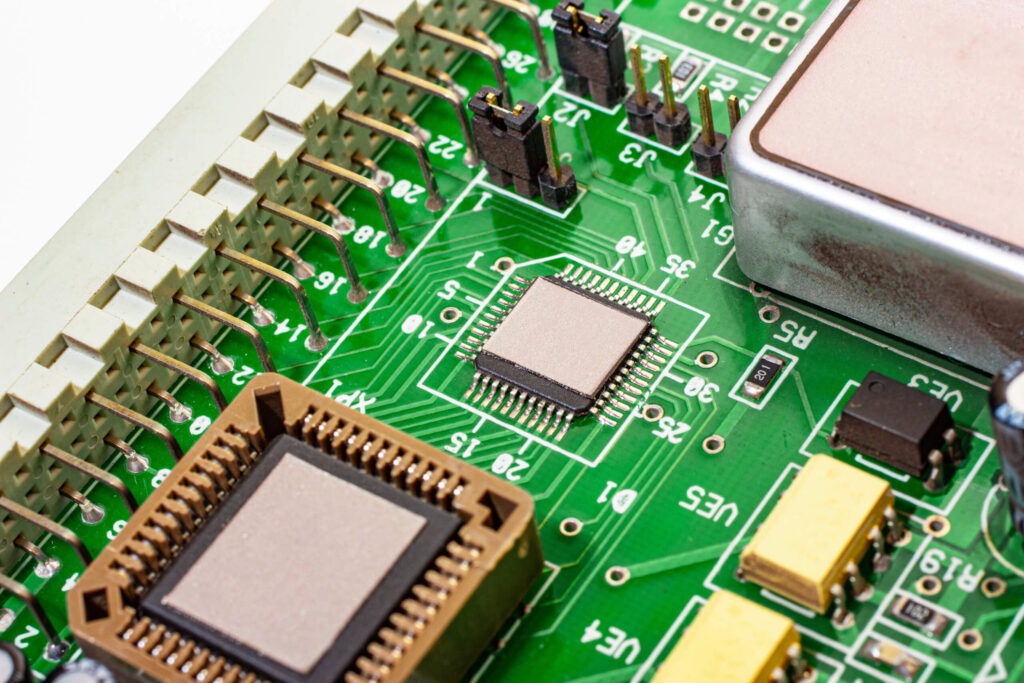

Maddox AI specialises in performing AI-based inspections and ensuring that electronic components are flawless. In particular, Maddox AI is used for the inspection of printed circuit boards, semiconductors, electrical hardware and other electronic components. The classic inspection is often combined with the scanning of QR and barcodes to guarantee one hundred percent traceability of the products.

Areas of Application for Maddox AI in the Electrical Industry

In the electrical industry, precise inspections and strict quality controls are required to ensure that electronic devices are fault-free and function safely. Maddox AI offers a variety of visual quality control solutions that meet the specific requirements of this industry. With Maddox AI, companies in the electronics industry receive solutions tailored to their specific requirements. From the inspection of housings and surfaces for scratches, dents and other defects to the precise inspection of imprints, labels and packaging. Even the smallest subtle deviations in surface structures, paintwork, printing and processing can be identified. Maddox AI therefore not only detects obvious defects, but also the smallest irregularities that the human eye can overlook due to fatigue.

With Maddox AI, every automation project is also always a digitisation project. Maddox AI processes the data acquired during the automatic visual inspection, including images and metadata, in the cloud software to enable detailed analyses such as defect Pareto analyses, defect heat maps and dashboards. You will be informed immediately by Maddox AI (e.g. via email or SMS) if too much scrap is produced. In this way, you can ensure that excessive scrap does not occur over a longer period of time.

The Following Use Cases, Among Others, Can Be Inspected Through Maddox AI:

Inspection of printed circuit boards: Aaccuracy in identifying trace defects and superficial defects on printed circuit boards to ensure electrical functionality.

Inspection of cabling: Visual inspection of wiring for correct connections and insulation to prevent short circuits and malfunctions.

Analysis of electronic components: Detection of defects in chips, capacitors and other components for reliable functionality of electronic devices.

Inspection of enclosures and materials: Inspection of enclosures for cracks, abrasion and irregularities to ensure the longevity and safety of the equipment.

Identification of contaminants: Detection of dust, moisture or other contaminants that could affect electronic components.

Control and display analysis: Inspection of controls and displays for scratches, cracks and irregularities for an optimal user experience.

Detection of inclusions and foreign objects: Identification of inclusions, foreign objects or irregularities.

Identification of part numbers and embossing: Accurately capture part numbers as well as engravings and embossing on components using OCR to enable accurate matching and prevent misordering.

Bar and QR code reading: Recognition of codes for accurate identification and verification of parts and products.

Traceability of products: Complete traceability of products from manufacturing to the end user to ensure safety and quality throughout the supply chain.

Example: Inspection of Printed Circuit Boards

Do you have questions about specific possible applications of Maddox AI?

Our experts will be happy to advise you!