White Paper: Reality Check in Quality Control:

Underestimated Weaknesses of Manual Inspections

In a survey of over 100 quality experts, we were able to demonstrate that while the limitations of manual quality control are generally recognized, their actual extent is often underestimated. Failure to adequately address these risks in manual inspection inevitably leads to high costs resulting from customer complaints or false rejects.

Peter Droege

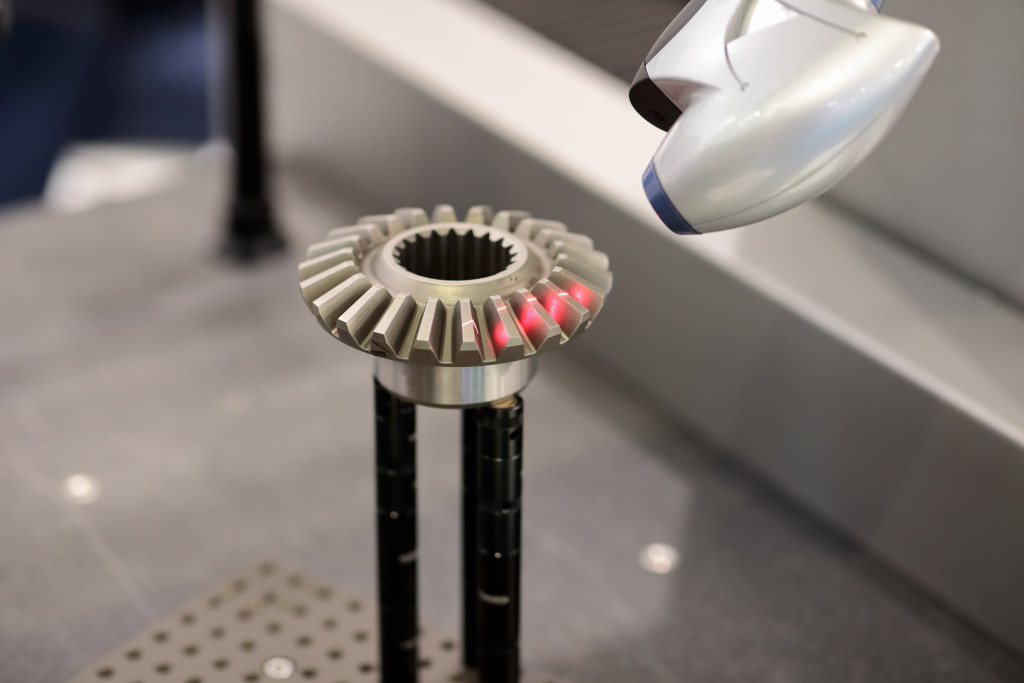

AI-Based Support for Quality Experts

AI-based inspection systems offer a solution and can achieve inspection accuracies comparable to those of an ever-attentive human inspector. Given that human inspectors' defect annotations serve as the basis for AI-based inspection systems, the limitations of manual controls play a pivotal role in developing robust AI systems. Even the most advanced AI algorithm cannot achieve optimal inspection accuracy if it relies on inconsistent training data. Long story short: Without a consistent defect definition, the developed AI model will not be accurate.

The good news is that solutions such as Maddox AI support quality experts with various digital tools to create a consistent defect definition and thus consistent training data. A high quality training dataset ultimately leads to highly accurate AI models.

Secure Your Free White Paper!

Why Only Few Companies Actually Use AI-Based Inspection Systems