Inspection Cell for Plastic Seals

Surface Inspection

Customer Request

Our customer manufactures over 10,000 seals daily, which were originally inspected manually by twelve people working in three shifts. Depending on the shift and personnel, the sorting accuracy varied considerably. The company refrained from using classic, rule-based inspection systems. It was feared that these systems could only inadequately deal with the high production variability, as the seals come out of the injection molding machine slightly differently depending on the batch and status of the mold.

Maddox AI has developed a three-camera inspection cell that rotates the seals 360° and inspects them 100% from all sides. The device is used to detect burrs, bubbles and contamination, among other things. The gaskets are clamped manually, while the inspection, sorting and packaging preparation is fully automated.

The gaskets were manually inspected in three shifts with a total of twelve operators. The detection accuracy varied depending on the inspector.

All products are inspected 100% automatically according to a precise defect definition. The inspection system is operated by one employee per shift.

The plant received an average of one to two customer complaints per year, which had to be manually rechecked.

No further customer complaints have been received since the installation of Maddox AI.

Since the inspection results were not digitized, no regular structured root cause analysis was performed.

Thanks to the digitized inspection process, several process optimizations could be realized (e.g. employee training for tool change).

Sounds like what you need?

Do you have questions about this solution or your very specific application?

Our experts will be happy to advise you!

More Case Studies

Browse through some of our selected case studies. If you have any questions about individual examples or your specific use case, please feel free to contact us at any time!

Pharmaceutical and Medical

- All

- Automotive

- Consumer Goods

- Electronical

- Energy Technology

- Food and Beverages

- Logistics

- Metal

- Pharmaceutical and Medical

- Plastic

Component Detection

- All

- Code Recognition

- Component Detection

- Positioning Errors

- Surface Inspection

Cardboard

- All

- Cardboard

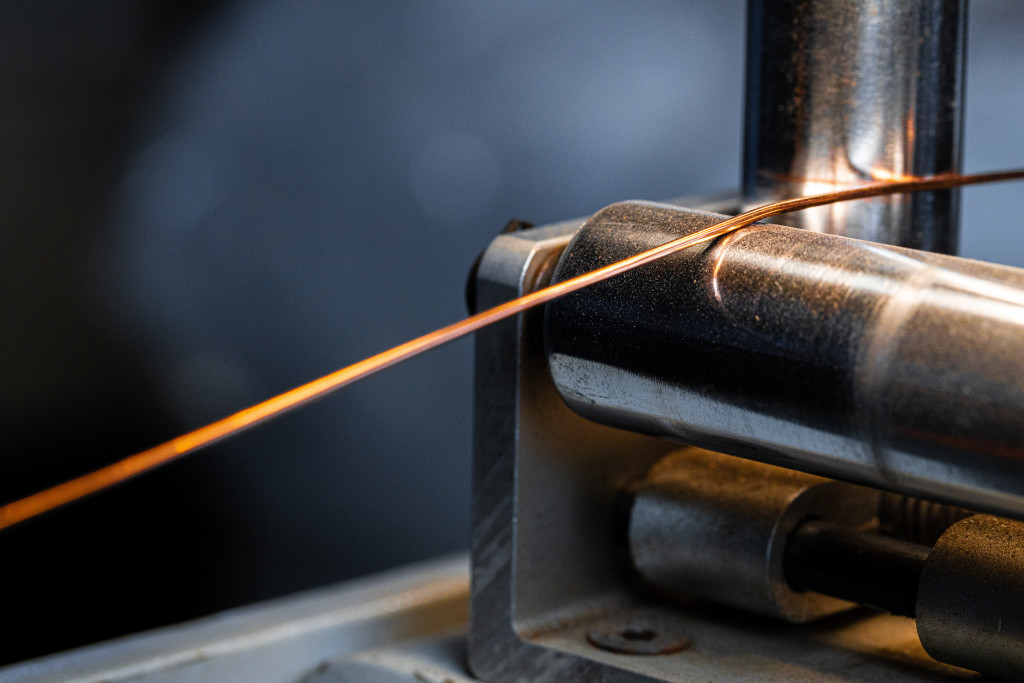

- Copper

- Dough

- Metal

- Paper

- Plastic

- Rubber

- Steel