Optimization of Turned Parts Inspection

Surface Inspection

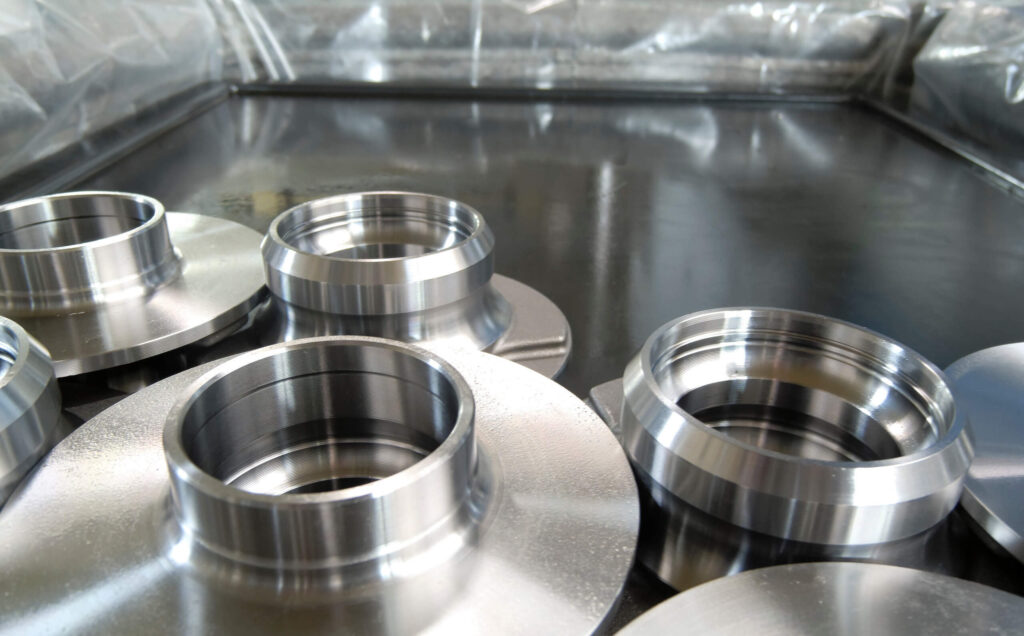

Customer Request

Our customer manufactures turned parts in the million range for the automotive industry. These were manually inspected by several employees. Depending on the shift and personnel, the sorting accuracy varied considerably. In the past, classic rule-based inspection systems had already been tested. However, these were no longer used as the effort to recalibrate the systems was too high in the context of a dynamic production.

Maddox AI has developed a semi-automatic inspection system that uses three cameras to inspect turned parts 100% from all sides (top, bottom, mantle surface). The system is used to detect scratches and impact marks, among other things.

The turned parts were checked manually in three shifts with a total of six employees. The detection accuracy varied depending on the inspector.

All products are inspected 100% automatically according to a precise defect definition. The inspection system is operated by one employee per shift.

The plant received one significant customer complaint, which had to be manually rechecked.

No further customer complaints have been received after the installation of Maddox AI.

Since the inspection results were not digitized, no regular structured root cause analysis was performed.

Thanks to the digitized inspection process, process optimizations could be realized (e.g. direct feedback loop for machine setting).

Sounds like what you need?

Do you have questions about this solution or your very specific application?

Our experts will be happy to advise you!

More Case Studies

Browse through some of our selected case studies. If you have any questions about individual examples or your specific use case, please feel free to contact us at any time!

Pharmaceutical and Medical

- All

- Automotive

- Consumer Goods

- Electronical

- Energy Technology

- Food and Beverages

- Logistics

- Metal

- Pharmaceutical and Medical

- Plastic

Component Detection

- All

- Code Recognition

- Component Detection

- Positioning Errors

- Surface Inspection

Cardboard

- All

- Cardboard

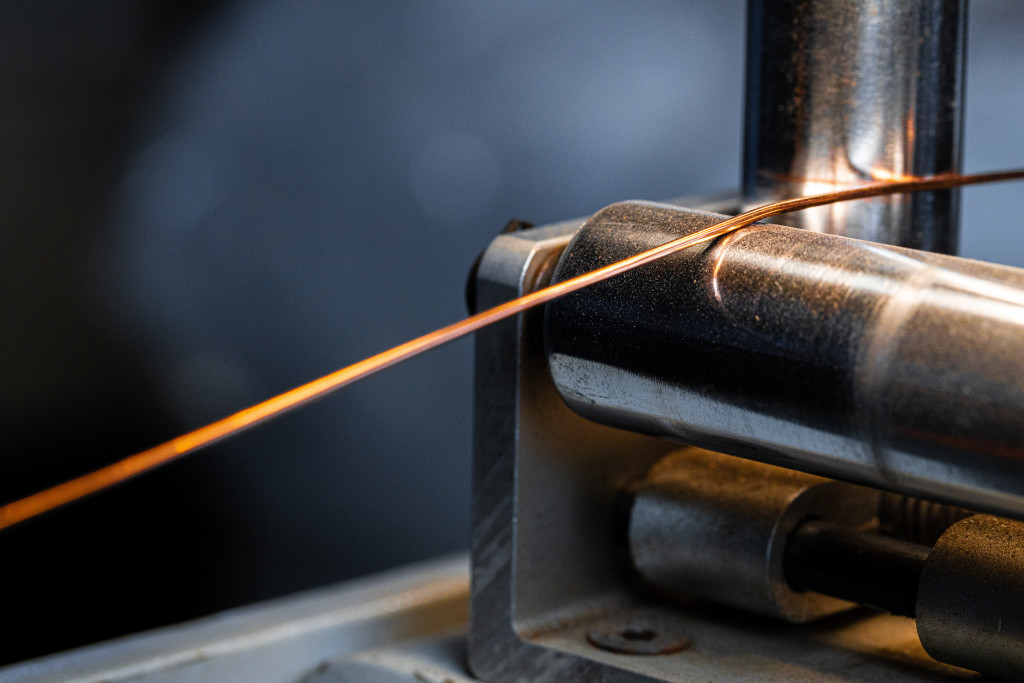

- Copper

- Dough

- Metal

- Paper

- Plastic

- Rubber

- Steel